Empowering Visionaries to Create Chip Wonders

Our team consists of seasoned professionals with versatile experience in digital, Analog and mixed signal, RF IC and verfication

Strategic Partnership for Enduring Growth

Fuel your business’s enduring growth through strategic partnerships that drive innovation, collaboration, and long-term success.

WHAT WE DO?

At VTT Global IC Design Center, we specialize in empowering visionaries to create chip wonders. Our seasoned professionals offer expertise in digital, analog and mixed-signal, & RF IC design, as well as verification services. We excel in translating conceptual ideas into high-performance silicon chips, ensuring optimal performance and reliability across diverse applications. With a focus on rigorous verification and adherence to industry standards, we deliver exceptional results that exceed customer expectations.

EXPERTISE AND STRENGTHS

With experience across various technologies and a mastery of industry-standard tools, we ensure top-notch quality in every project.

IC Design

Analog and Mixed Signal

Verification

RF IC

Microprocessor Design

Training

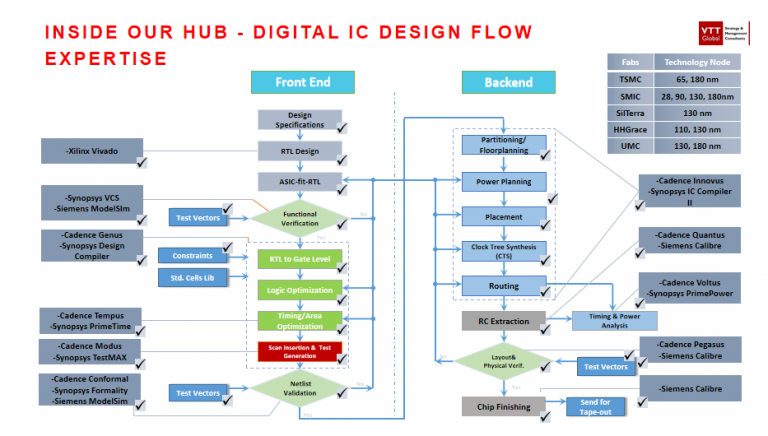

Digital IC Design Flow

Sure, here’s a simplified explanation of the digital integrated circuit (IC) design flow:

1. Specification

The process begins with defining the functionality and performance requirements of the IC. This involves understanding the purpose of the chip, its intended application, and the constraints it must adhere to (such as power consumption, speed, and area).

2. Architecture Design

In this phase, high-level decisions about the architecture of the IC are made. This includes selecting the overall system architecture, partitioning the design into functional blocks, and defining the interfaces between these blocks.

3. RTL Design:

Register Transfer Level (RTL) design involves describing the behavior of the digital circuit at a higher level of abstraction using a hardware description language (HDL) such as Verilog or VHDL. Engineers write code to describe the functionality of each block in the design.

4. Functional Verification

Once the RTL design is complete, it needs to be verified to ensure that it behaves as intended. Simulation techniques are used to test the design under various conditions and scenarios to catch any functional bugs or errors.

5. Synthesis

Synthesis is the process of translating the RTL description into a gate-level netlist. This involves mapping the high-level RTL constructs to actual logic gates and flip-flops from a library of standard cells. The result is a design expressed in terms of logic gates and interconnections.

6. Design for Testability (DFT)

DFT techniques are applied to the synthesized netlist to ensure that the manufactured IC can be efficiently tested for faults and defects. This involves adding special circuitry for test access and implementing test patterns for fault detection.

7. Physical Design

In this phase, the physical layout of the IC is created. This involves floor planning, where the placement of logic blocks and other components is determined, and routing, where the interconnections between these blocks are established while meeting timing, power, and area constraints.

8. Timing Closure

Timing closure is the process of ensuring that all timing requirements, such as clock frequencies and signal propagation delays, are met. This may involve iterative adjustments to the physical design to optimize timing and signal integrity.

9. Design Verification

Once the physical design is complete, it needs to be verified to ensure that it meets the original specification and functional requirements. This involves a combination of simulation, formal verification, and sometimes hardware emulation or prototyping.

10. Physical Verification

Physical verification involves checking the layout of the IC for manufacturing issues such as spacing violations, electrical rule violations, and other design rule violations. This is crucial to ensure that the IC can be manufactured reliably.

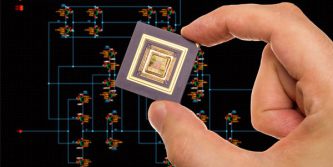

11. Manufacturing

Once the design has been verified and validated, it is sent for manufacturing. This involves fabricating the IC on a silicon wafer using processes such as photolithography, etching, and doping.

12. Testing and Packaging

After manufacturing, the ICs undergo testing to ensure that they function correctly. Defective chips are discarded, while good chips are packaged into final semiconductor packages for distribution and use in electronic devices.

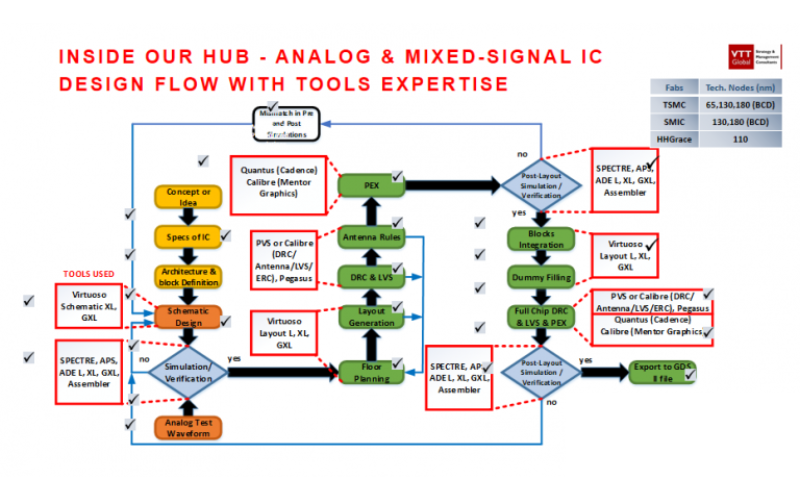

Analog and Mixed Signal Design Flow

Certainly, here are the steps involved in the analog and mixed-signal IC design flow:

1. Specification Definition

Define the functionality and performance requirements of the IC.

2. Architectural Exploration

Explore different architectural options and partition the system accordingly.

3. Analog Block Design

Design and simulate analog circuits, considering transistor-level details for critical components.

4. Digital Integration

Integrate digital components into the design, ensuring compatibility and addressing power supply noise and signal integrity issues.

5. Verification

Verify the functionality and electrical characteristics of the design through simulation, emulation, and prototyping.

6. Layout Design

Meticulously design the layout considering parasitic effects, manufacturability, and area constraints.

7. Physical Verification

Perform physical verification checks to ensure the layout adheres to design rules and is ready for fabrication.

SERVICES

We offer a compelling value proposition aimed at expediting product development cycles while maintaining efficiency and agility. Our services include:

Customization & Flexibility

Seamless Technology Integration

Industry standard compliance

Technical support & collaboration

Guaranteed Confidentiality

Accelerate Time-toMarket

Adequate availibility of advance technology

Cost-Effective Solutions

OUR STRENGTH

Our team consists of seasoned professionals with versatile experience in analog, digital and mixed signal IC design

Unlock You Business Potential With Our Expertise

From strategic guidance and innovative solutions, VTT Global is your trusted partner in navigating complexity, delivering results, and building stronger businesses.